Floppy Storage Need Solved

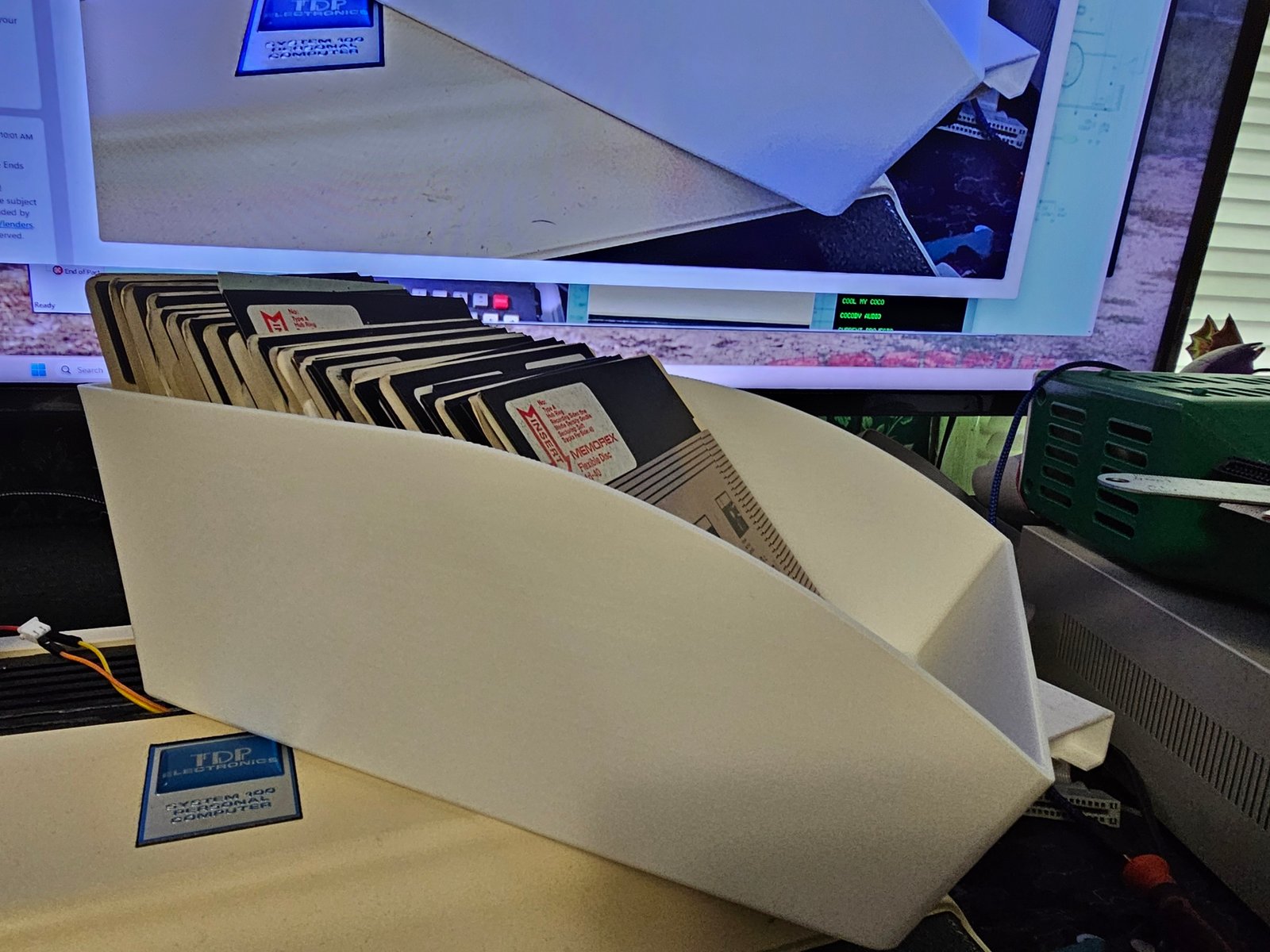

What to do when you buy floppies and realize you have no safe storage? Then you realize the zip-lock baggie they were sent in may provide safety from dust, but noting else.

Well, when you have a 3d printer and some free time to design something you already have a real world solution. or rather, a modern solution to an 8 bit problem. Now, in all fairness, I did seriously consider finding floppy case on e-bay. However, like many other retro related things, the sellers do think very highly of their items.

So I spent a little time with my design software, and after a couple of test prints (it ALWAYS seems to take three tests before a good proof of concept), I think this turned out quite well.

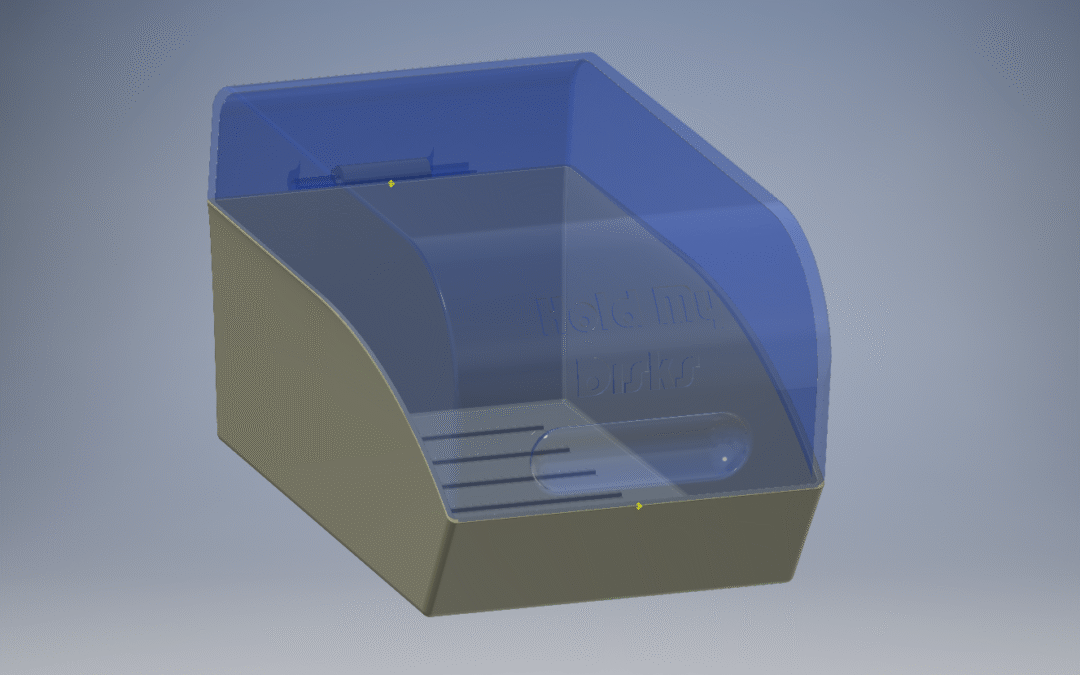

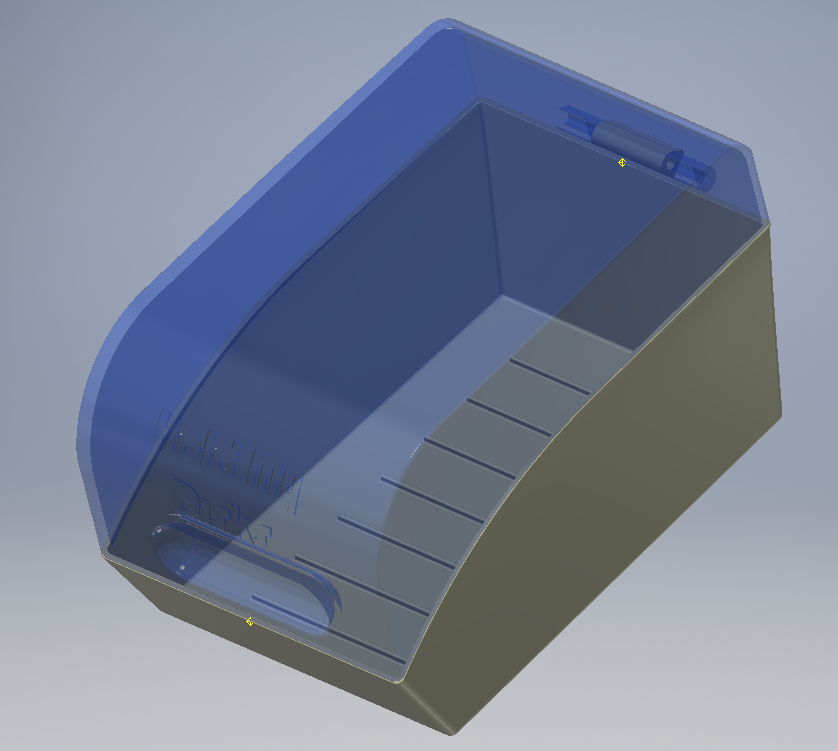

My first good test print – the one where the disks fit properly – was running before I got the bright idea to design a lid with a hinge to go along with it. Completing the design, as such, was insprired by the effort Antonio Caballero put into his Tower of Power cart storage units.

Below is an image of just the bottom, I’ve ran out of time this weekend for doing much more, but during the week, I’ll print out a fully hinged version. This is certainly less expensive than the e-bay units, and quicker. Due to the size of these (this one comfortably holds 45 floppies) the top and bottom each take roughly 16 hours to print.

Update June 24, 2025

So I went ahead and printed out a new base and lid with the hinges designed in. For the images below, I got creative, or retro hack-job, you decide – I used a Q-Tip for the hinge-pin. I’ll print out a real hinge-pin later this week. Currently it’s 96 degrees F here in Maine, and I have zero interest in making my room any warmer. Overall, I’m about 90% happy with these results. The radius tells me I should have used supports – which require post processing (priming, sanding, filling, more priming, etc…). I may change the design from a radius to an angled front. An angle of 45 degrees should work fine.

Post-processing is a pain in the neck, and I really don’t have time for that usually. So, when I design something I try to design it so that supports aren’t needed – I should’ve known that large of a radius would come out iffy. My Anycubic Kobra Max is a workhorse, but with larger prints and the speed it prints, bridging and overhangs are tough to pre-tune sometimes.